|

Henan Doing Mechanical Equipment

|

Tyre pyrolysis plant to fuel oil

| Price: | 45000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

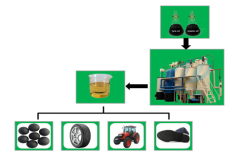

Doing produced pyrolysis plant ,the pyrolysis plant can recycling waste tire/plastic/rubbber and convert waste tyre/plastic/rubber to fuel oil .

Tyre pyrolysis plant

Cars have been a need in our daily life, and more and more cars mean creating more and more waste tyres. In this manner, how to manage these waste tyres has turned into a troublesome issue. Besides recycling waste tyres by using shredder machine or rubber powder production line for further reprocessing, Doing group has developed the latest waste tyre pyrolysis plant for sale to deal with the waste tyres in an eco-friendly and profitable method. The tyre pyrolysis plant also can be used to dispose waste plastic, waste rubber, medical waste, oil sludge, etc.

www(dot)wastetireoil(dot)com

Tyre pyrolysis plant feature

Tyre pyrolysis plant

It is the most cost effective wastage tyre recycling technology in the world.

It results in 100% wastage tyre recycling. There is no churn left after the process.

No use of chemical ingredients, therefore, the process is environment friendly.

No case of soil, water or air pollution.

It generates economically valuable products out of waste tyres.

Generated products have good market value and demand.

Raw material (wastage tyre) is cheap and easily available.www(dot)wastetireoil(dot)com Each recycled ton of tyres preserves 10 tons of carbon dioxide (CO2) that is a major green house gas. Therefore, it can help in the reduction of greenhouse gas from the environment.

The process can be effectively applied to all rubber based waste materials for recycling and generation of commercially valuable products.

The system creates an alternate source of energy to reduce the burden on petroleum products and natural gases.

The system gives an opportunity to the government and local administrations to deal with the wastage tyre problems.

The Pyrolysis process has duration of 4 to 12 hours, based on quantity and size of tyre (car tyre, truck tyre, etc.).

During the process different vacuum values are applied in pre-determined temperatures and in different phases.

Different gases are obtained and the condensed gas is stored as a fuel oil in the tanks.

Two valuable products – carbon black and tyre oil are obtained from the wastage tyres.

The device has excellent safety and environmental protection property.

The residue left after the recycling process of waste tyres is carbon black, there is no waste solid left.

Waste tyre pyrolysis plant working process www(dot)wastetireoil(dot)com

Tyre pyrolysis plant working process

Feed waste tyres into reactor by auto-feeder or manual and seal the feeding inlet door tightly to make sure there is no gas leakage.

2. Then heat the reactor by using coal, charcoal, fuel gas, wood etc. as heating materials. The reactor will be slowly heated, and when the temperature reach about 250℃, the oil gas will be formed.

3. The pyrolysis oil gas coming out from the reactor then goes to condensing system and becomes liquid oil. We adopt new-type condenser which can improve the oil yield efficiency and make the oil yield to the maximum.

4. The gas which can't be liquefied under normal pressure will be designed to go back to combustion system through safety device. It can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

5. After finishing oil production, the temperature of the reactor will be cooled down. When the temperature falls down to 40℃, the carbon black and steel wire will be discharged automatically or by manual.

Final product application of waste tyre pyrolysis plant www(dot)wastetireoil(dot)com

1. The pyrolysis oil from waste tyre pyrolysis plant for sale can be widely used as industrial fuel materials for burning. If further refined to diesel or gasoline by the waste oil distillation machine, the oil can be used in low speed engines such as digging machine, road roller or loading machine, etc. It can help in relieving energy crisis.

2. The carbon black from tyre pyrolysis can be used for construction bricks with clay or used as fuel. If further processed by Doing group carbon black processing plant, the carbon black can be deep processed into N220, N330 carbon black, which has higher value and wider applications. Moreover, it can be made into pellet or briquette for burning, or further processed into color master batch as basic material to make pipes, cable jacket etc.

3. The steel wire can be reprocessed or used to make steel and iron rod.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Skype: bonniezhao2